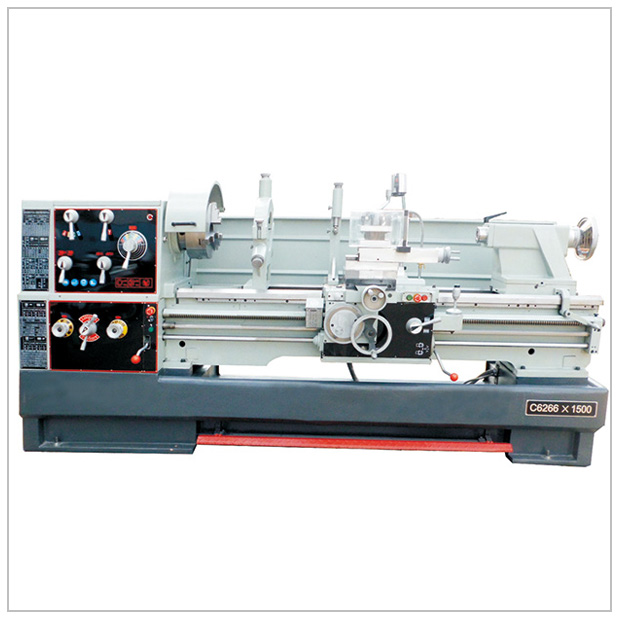

Lathe

1. Do you know the main differences between lathe and milling machine?

① Lathe machine is generally used for processing shaft, sleeve, disc, pad and other parts. However, milling machine is usually used for machining grooves and milling planes.

② Generally, the machining form of lathe is the feed movement of cutter, and the main movement is the workpiece rotation motion. The milling machine is just opposite to the lathe. The main movement is the rotation of the milling cutter, and the movement of the workpiece is used as the feed motion.

③ Horizontal lathe machine is the most common lathe type. However, vertical milling machine, horizontal milling machine and universal milling machine are more common milling machine types in daily use.

2. What are the main components and the advantages of lathe machine?

The main components of an ordinary lathe: the bed, spindle box, feed box, slide box, knife holder, tailstock, light bar and guide screw. The advantages of lathe include:

① The lathe machine is powerful and has stable output.

② The spindle bore is large, the worktable size is large, and the bed rail width is wide.

③ The machine bed is made of one body casting, which makes the machine have good stability and long service life.

④ The machine tool has high precision and strong anti-interference ability.

⑤ Easy to operate and high efficiency.

3. How do customers evaluate the lathe equipment?

“The lathe produced by DXMC has been used in practice, the quality is stable and the price is reasonable. Our cooperation went very well and made a good impression on me.”

----A Russian customer

“I often buy machine tools in China. Manufacturers warmly invited me to field visits, DXMC lathe cost-effective, quality is guaranteed, we have established a long-term cooperative relationship.”

----An Indonesian customer